Working principle of machine

It is used for the processing of products that need high frequency welding and synchronous cutting. The working principle of high frequency welding machine is to use high frequency welding first and then cut off at the same time through the pressure device equipped with the machine. Because it is completed at the same time, so called high frequency synchronous fuses.

Working principle of machine

It is used for the processing of products that need high frequency welding and synchronous cutting. The working principle of high frequency welding machine is to use high frequency welding first and then cut off at the same time through the pressure device equipped with the machine. Because it is completed at the same time, so called high frequency synchronous fuses.

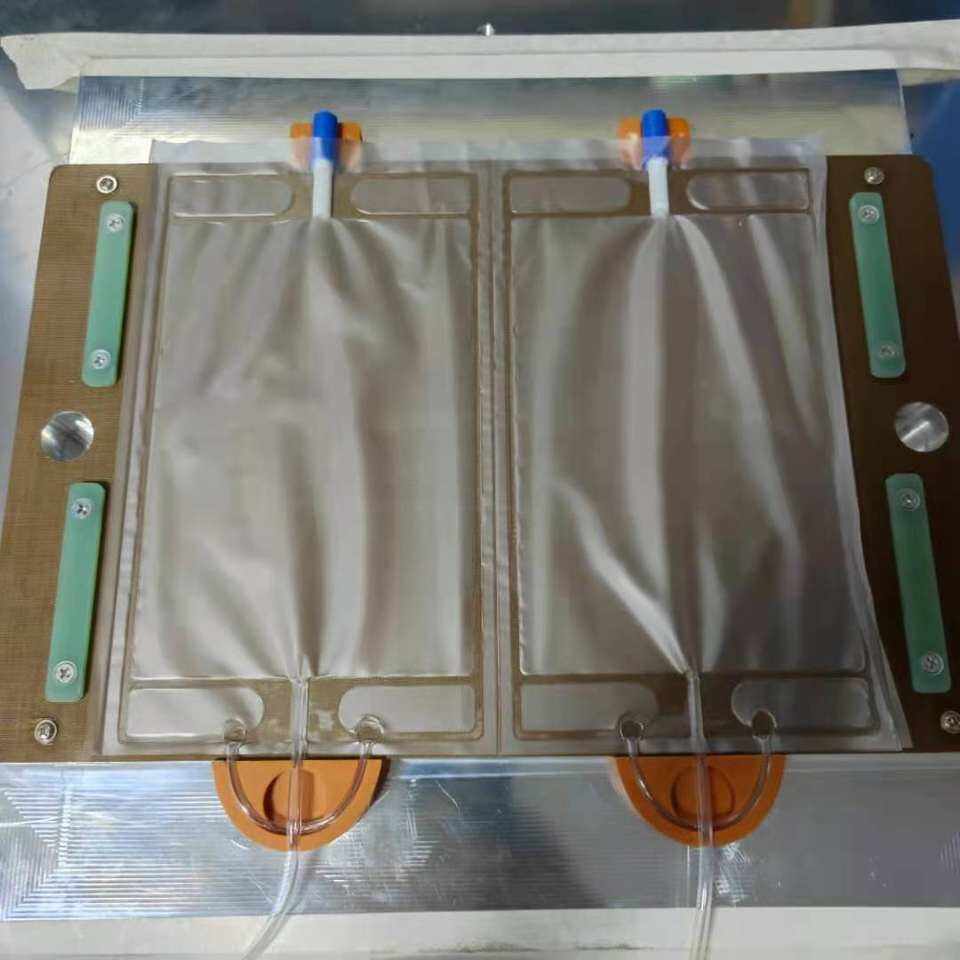

Main Feactures:

1.The frame adopts four-column gantry structure with good flatness

2.The machine is thermostatic and the heating temperature is even

3.Two-stage supercharging: one is welding function, one is cutting function

4.2 stations, automatic pusher

5.OMRON digital temperature controller with high precision

6.Pressure cylinder:ensure sufficient pressure for welding and cutting process

7.The heating plate is insulated to maintain a constant temperature

8.Nickel-cobalt heating device

9.Capacity: 300—400pcs/hour/2 workers

Parameter

Model |

CH-8KW-DSRD |

CH-12KW-DSRD |

CH-15KW-DSRD |

Voltage |

220V/380V 3P 50/60HZ |

||

Power |

8KW |

12KW |

15KW |

Input Power |

10KVA |

15KVA |

25KVA |

Oscillation frequency |

27.12MHZ |

27.12MHZ |

27.12MHZ |

Oscillation Tube |

7T69RB |

E3130 |

8T85RB |

Anti-Spark System |

NL-5557 |

NL-5557 |

NL-5557 |

Max Pressure |

10Ton |

20Ton |

30Ton |

Working Table Size |

350*450MM |

400*600MM |

400*600MM |

Machine Dimension |

2300*1560*2300mm |

2100*1500*2300mm |

2000*2350*2150mm |

Machine Net Weight |

1100KG |

1300KG |

1500KG |