×

×

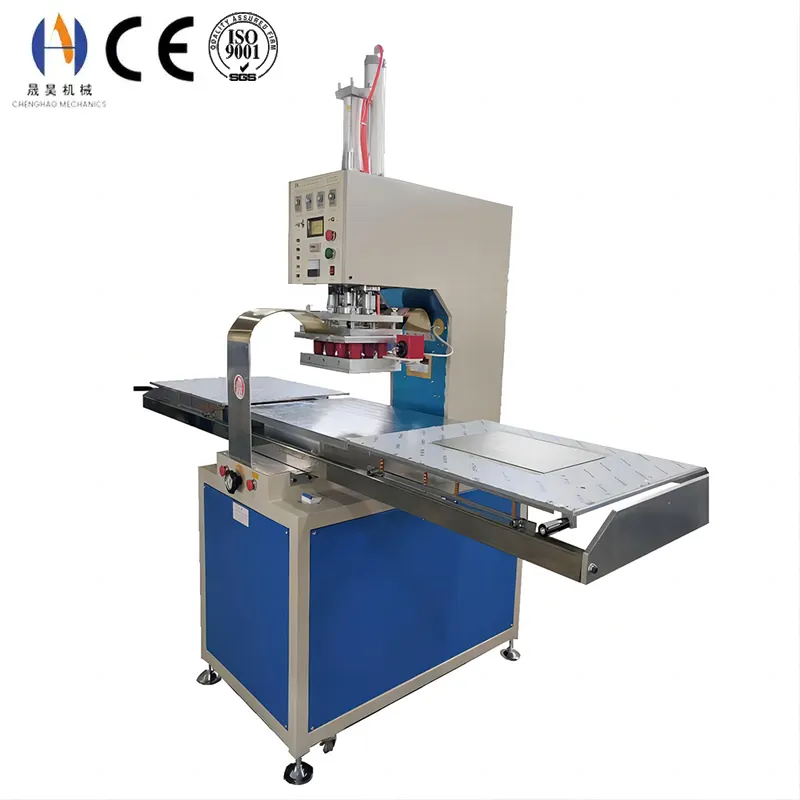

HF-sveiseapparater er viktige utstyr i produksjon i dag på grunn av deres unike arbeidsprinsipper og brede bruksområder. Ved å bruke unike metoder har CHENGHAO utviklet og levert moderne maskinløsninger som et bredt utvalg av hf sveise maskiner for å imøtekomme og møte ulike industrielle krav. Denne artikkelen har som mål å forklare arbeidsprinsippet til et HF-sveiseapparat, samt dets betydelige rolle i industrien.

Arbeidsprinsippet for HF-sømmaskiner

HF-sveising, bredt kjent som RF-sveising eller høyfrekvenssveising, er en prosess for sveising som sammenføyer termoplastiske materialer ved hjelp av elektromagnetisk energi, og produserer høyfrekvente elektriske strømmer. Maskinen selv skaper elektriske strømmer, som beveger seg gjennom materialet, og genererer varme på grunn av molekylær friksjon. Den genererte varmen mykner materialet, som deretter kan presses sammen, under trykk, og bindes.

Nøkkelkomponenter i HF-sveise-maskiner

Elektromagnetisk generator: Denne komponenten av maskinen syntetiserer de høyfrekvente elektriske feltene som er nødvendige for å fullføre sveiseaktiviteten på materialet.

Elektroder: Denne delen av maskinen gir trykk på materialet samt tillater strøm å flyte gjennom, noe som muliggjør den nødvendige varmen som genereres for å sveise komponentene sammen.

Kjølesystem: Beskytter maskinen fra å nå siden når temperaturene blir for høye, i prosessen med å prøve å opprettholde en ideell driftstemperatur for maskinen.

Fordeler med HF-sveiseapparater

Hastighet: HF-sveising er raskt, noe som hjelper med en raskere produktutgang i masseproduksjon.

Presis: Varme påføres på en kontrollert måte som ytterligere hjelper med nøyaktige sveiser.

Allsidig: HF-sveising kan brukes på mange termoplastiske materialer som PVC, polyuretan og gummi.

Økonomisk: Denne metoden bruker mindre energi og involverer minimal materialbehandling, noe som igjen senker produksjonskostnadene.

Anvendelsesområder for HF-sveiseapparater

HF-sveiseapparater finner anvendelse i mange sektorer.

Bilindustri: For sveising av vinyl, plast og gummi i bilens innvendige deler.

Medisin: Brukes i produksjonen av oppblåsbare medisinske gjenstander, blodposer og katetre.

Tekstil: For vanntette klær, presenninger og andre tekstilprodukter.

Emballasje: Brukes til å forsegle plastposer og sekker.

CHENGHAOs bidrag til industrien

Ved å bruke avansert teknologi produserer CHENGHAO HF-sveiseapparater som oppfyller produksjonsbehovene til ulike industrier. Produktene deres er enkle å bruke, pålitelige og effektive, noe som hjelper dem med å vinne tillit fra mange selskaper og øker deres samlede produktivitet.

Leveringen av disse maskinene har blitt muliggjort med hjelp av moderne teknologier som HF-sveising. CHENGHAO vil videre integrere moderne teknologier for å forbedre effektiviteten til systemene som er svært viktige for moderne industrier. Med tanke på deres høye kvalitet og tilpasningsevne, vil HF-sveiseapparater tilfredsstille behovene til alle moderne industrier.