High-frequency (HF) welders are specialized machines used in the manufacturing industry for joining thermoplastic materials. They utilize electromagnetic waves to heat and fuse the materials together, creating strong and durable bonds. HF welders are commonly used in the production of products such as inflatable toys, medical devices, and automotive components.

Understanding the Principles of HF Welding

HF welding operates on the principle of dielectric heating, where the high-frequency electromagnetic waves cause the molecules in the thermoplastic material to vibrate and generate heat. This heat is concentrated at the interface between the materials, melting them and allowing them to bond when pressure is applied.

Strategies for Optimizing HF Welder Performance

Material Selection

The choice of materials is critical in optimizing HF welder performance. Not all thermoplastics are suitable for HF welding, and the wrong material can lead to poor weld quality or equipment damage. Selecting materials with appropriate dielectric properties ensures efficient energy transfer and a strong weld.

Equipment Calibration

Regular calibration of the HF welder is essential to maintain optimal performance. This includes adjusting the machine's power output, pressure settings, and welding time to match the specific material and product requirements. Proper calibration ensures consistent and reliable welds.

Maintenance and Cleaning

Proper maintenance and regular cleaning of the HF welder are crucial for preventing downtime and extending the machine's lifespan. This includes inspecting and replacing worn parts, cleaning the welding electrodes, and ensuring the cooling system is functioning correctly.

The Role of CHENGHAO in HF Welding Technology

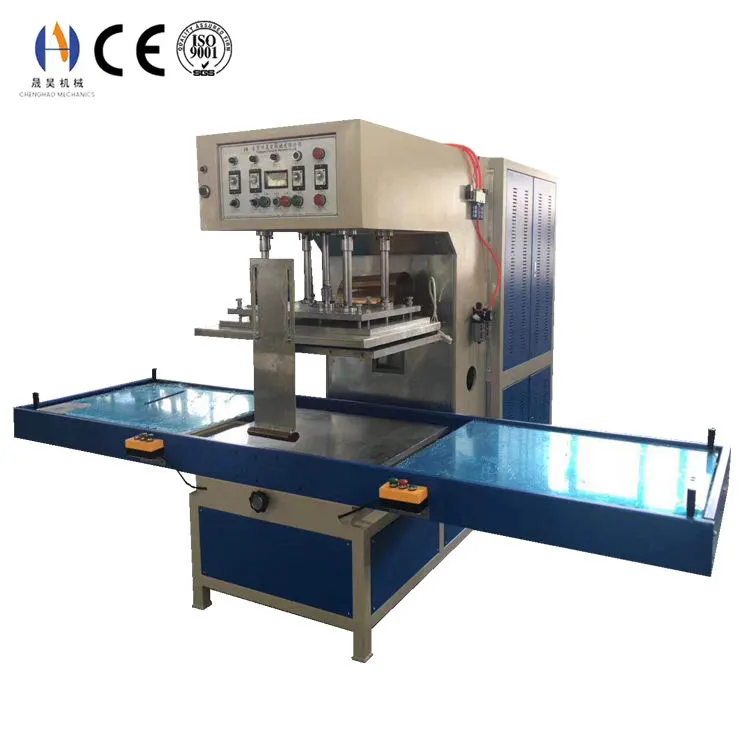

CHENGHAO is a company that specializes in the production of high-quality HF welding machines. Our commitment to excellence is evident in the meticulous craftsmanship and attention to detail in every machine we manufacture.

CHENGHAO's HF welders are designed with the latest technology, ensuring high efficiency and precision in the welding process. Our range of products includes specialized machines for various applications, such as the high-frequency stacked football welding machine and the high-frequency glove welding machine.

Conclusion

Optimizing the performance of HF welders is essential for achieving high-quality welds and maximizing productivity in the manufacturing industry. CHENGHAO, with its advanced technology and dedication to quality, provides the tools necessary for manufacturers to achieve superior welding results. Whether it's through material selection, equipment calibration, or maintenance practices, CHENGHAO's HF welders are at the forefront of welding technology, delivering exceptional performance and reliability.