CHENGHAO radio frequency welding represents the future of filtration technology, offering a sustainable and cost-effective solution for water and air treatment. Our product is engineered to deliver exceptional results, even in the most challenging applications. Whether you're dealing with the removal of volatile organic compounds (VOCs) or the reduction of total organic carbon (TOC) levels, CHENGHAO radio frequency welding is up to the task. Its superior adsorption capacity and long-lasting performance make it a wise investment for any facility looking to optimize its filtration processes and reduce operational costs. With CHENGHAO radio frequency welding, you can rest assured that you're investing in a product that will stand the test of time and provide a reliable return on investment.

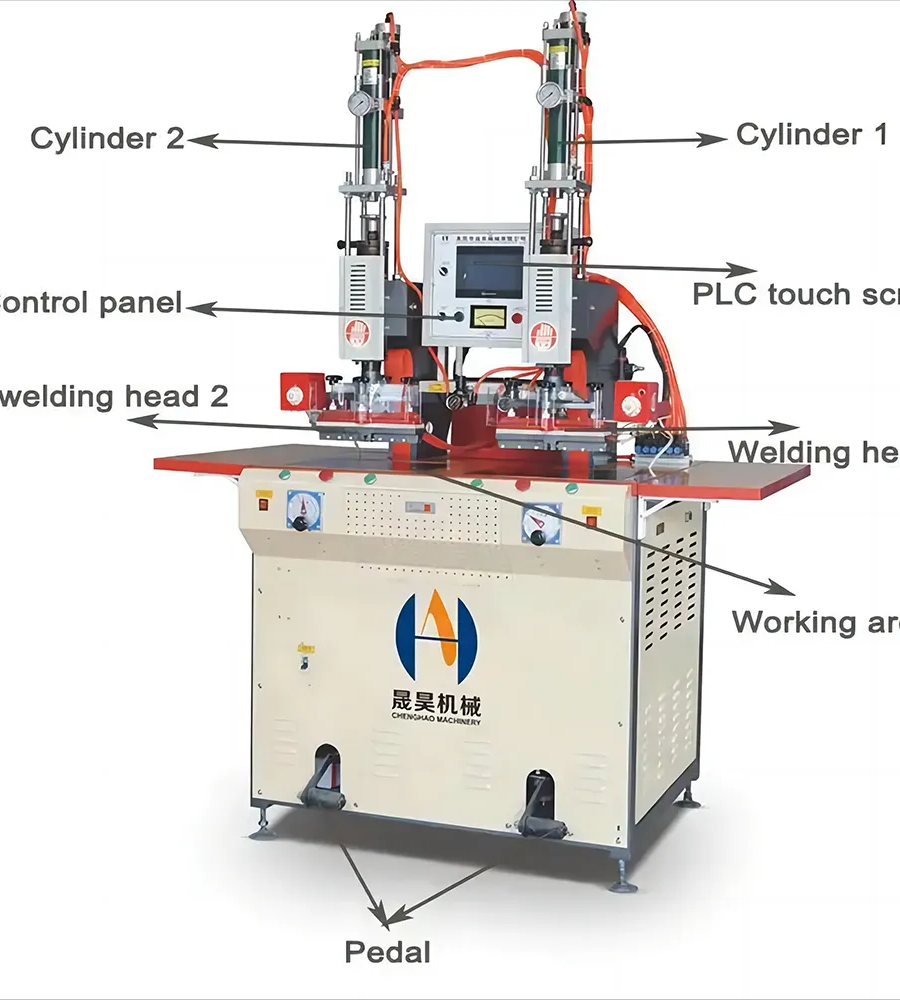

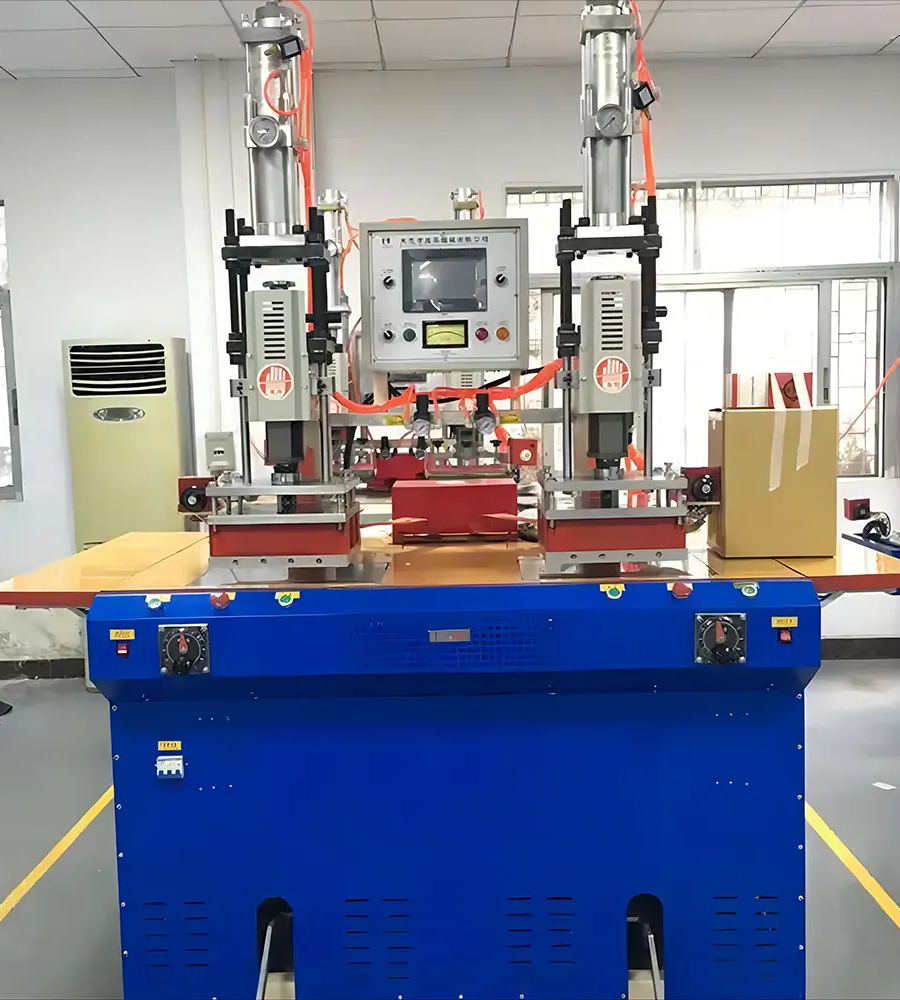

CHENGHAO radio frequency welding is a precision joining technology with a number of advanced features which make it unique in the industry. We have designed our welders to give consistent and dependable results so that all welds can be of highest quality and durability. CHENGHAO radio frequency welders are easy to use because they come with user-friendly interfaces as well as controls that are instinctive even for someone with minimal welding experience. Our machines can handle any type or size of job since they are made strong enough for heavy duty industrial applications but also compact and portable for small scale projects. What sets us apart at CHENGHAO is not only our commitment towards offering top notch welding solutions but also this being demonstrated through such equipments like the radio frequency welder itself!

In terms of speed and efficiency, CHENGHAO radio frequency welders are incomparable. I don't know how they do it but those welders work so fast! We designed them that way so you won't have to wait long for your projects to be done. Our chief aim is to provide precise and quick welding services through our machines which reduce on downtime while maximizing productivity at the same time. Additionally, with the use of advanced high frequency technology in these devices; heating occurs rapidly and remains steady throughout the whole process hence producing uniform quality joints always. Whether dealing with light or heavy fabrications; there is no problem because our products can be used universally thus making them an all-around essential tool for any workshop or factory setting. The world is moving very fast especially in manufacturing industries and this has prompted us at CHENGHAO Company limited to come up with these types of radiofrequency welders.

Choose CHENGHAO radio frequency welders and you get more than just a top-of-the-line welding machine; you also gain access to our team of dedicated customer support professionals. We pride ourselves on offering excellent service and assistance to customers starting from the time they buy their welder through setting it up, maintaining it as well as troubleshooting where necessary. Any time you have an inquiry or need technical help with your welder, our staff will always be there for you ensuring that each one of them is operating optimally. Here at CHENGHAO we understand that without satisfied clients we cannot succeed thus we strive towards exceeding expectations by far when dealing with these kinds of products – this is why every single one must work perfectly!

Safety and dependability are the two most important aspects of welding, which is why CHENGHAO radio frequency welders were created with these things in mind. Many safety features have been integrated into our machines to ensure operator protection all the time; for instance they have got overload protection as well as an automatic shut-off system. In addition, durability was considered during the making of this welder so that it can be able to handle heavy usage consistently over time: this is achieved through strong built quality coupled with high standard components used throughout its construction process. Our welders are designed for every day use no matter whether one works under harsh industrial conditions or within controlled workshop environments where performance may need to remain constant even after long hours of work. At CHENGHAO we think that there can never be too much attention paid towards safety or reliability which is why these principles serve as cornerstone upon which all our products are based including radio frequency welding units.

Dongguan Chenghao Machinery Co., Ltd. was established in 2007. It is a production-oriented modern enterprise integrating R&D, design, manufacturing, sales and technical services. It has passed the IS0 9001:2015 quality management system certification. The company is committed to the field of plastic welding, mainly producing high frequency machines, automatic blister sealing machines, ultrasonic welding machines and automation equipment.

Achieve intricate designs and textures on materials like leather and PVC, enhancing product aesthetics and brand appeal. Ideal for fashion accessories and automotive interiors.

Ensures uniform and controlled heating of materials before processing, optimizing molding and shaping processes. Perfect for industrial manufacturing and production efficiency.

Creates strong, airtight seals in packaging and product assembly, maintaining product freshness and integrity. Ideal for pharmaceuticals, food packaging, and electronics.

Delivers precise and durable welds on thermoplastics such as PVC and PU, ensuring structural integrity in automotive, medical, and electronics manufacturing. Enhances product reliability and performance.

CHENGHAO radio frequency welding technology offers several advantages, including rapid heating, precise control over welding parameters, and consistent weld quality. It ensures strong material bonds without the need for adhesives or additional materials, making it ideal for applications requiring reliable and efficient joining of materials.

Radio frequency welding utilizes electromagnetic waves to heat materials from within, resulting in fast and uniform heating. This method is particularly advantageous for thermoplastic materials, where it provides strong, hermetic seals without damaging sensitive components or causing thermal distortion.

CHENGHAO's radio frequency welding technology finds extensive use in industries such as automotive manufacturing (for airbag assemblies and interior components), medical device production (for fluid bags and tubing), and packaging (for sealing and forming). Its versatility and reliability make it suitable for a wide range of applications demanding precise and durable welds.

Yes, CHENGHAO offers customizable radio frequency welding solutions tailored to meet specific production requirements. Our engineering team works closely with clients to adjust welding parameters, electrode configurations, and material handling systems, ensuring optimal performance and integration into existing manufacturing processes.

CHENGHAO provides comprehensive support services, including installation, training for operators, and ongoing maintenance to ensure continued operational efficiency of our radio frequency welding equipment. Our technical experts are available to assist with troubleshooting, spare parts procurement, and upgrades, ensuring minimal downtime and maximum productivity for our clients.